PRESSES

How they work

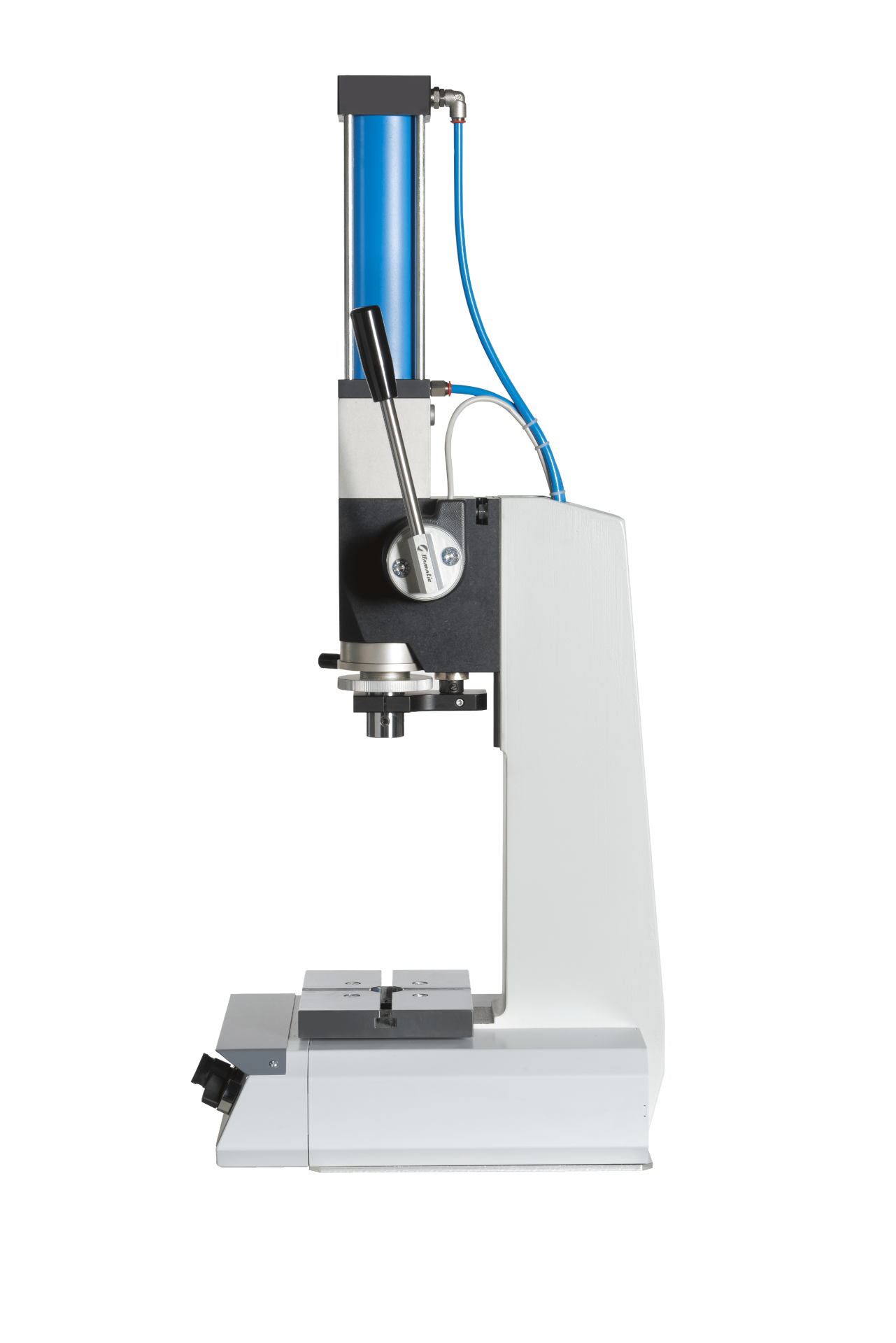

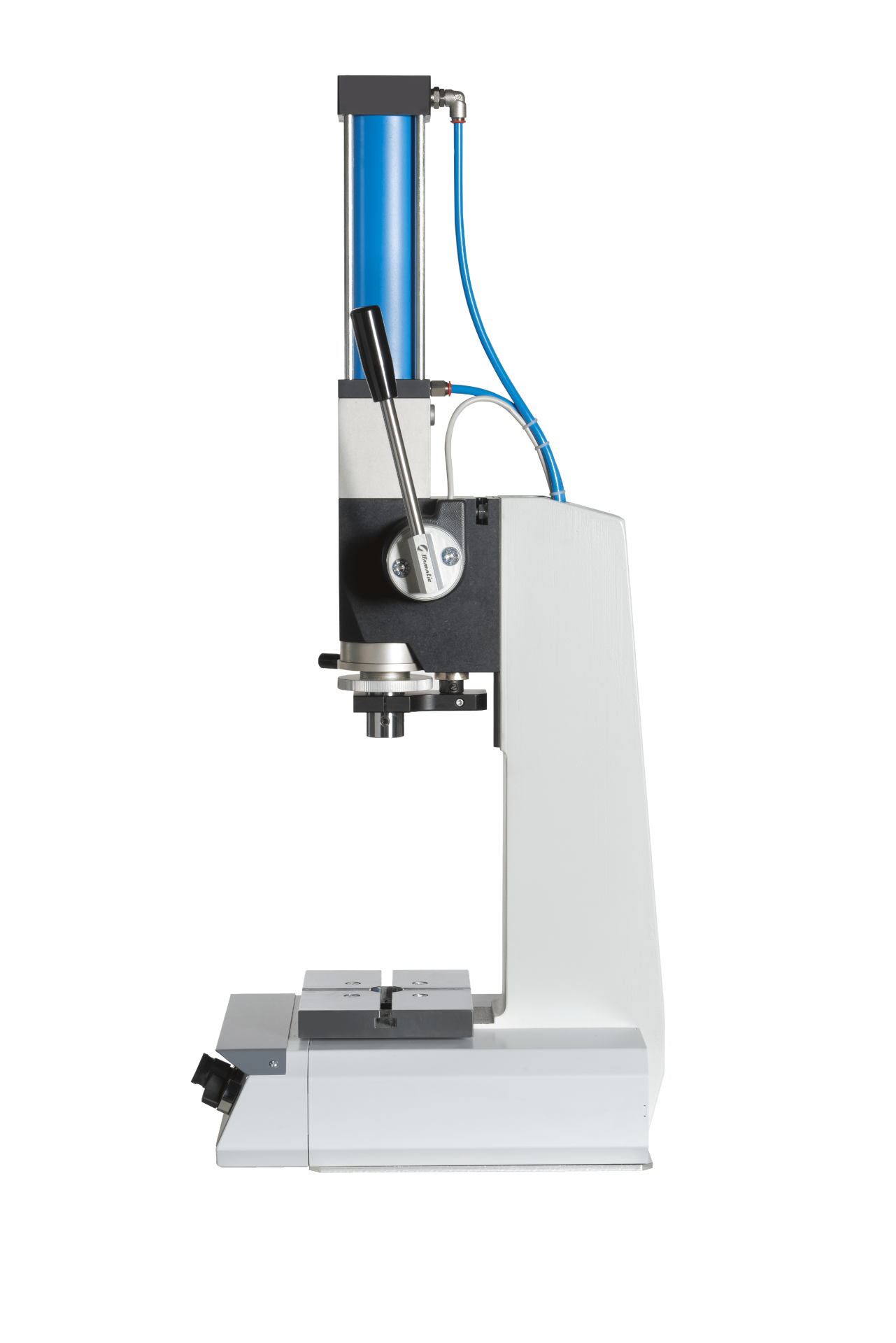

The MOP series presses work with compressed air up to 6 bar.

Thanks to the built-in pressure multiplier, they can develop high thrust forces without effort for the operator.

They combine the ease of use of a rack press with the thrust force of a hydraulic press.

Take a look at the video down below to see how they work.

High Flexibility of Applications

Bending

Drawing

Keying

Assembly

Clinching

Trimming

Chamfering

Marking

Straightening

Riveting

Pressing

Cutting

Compressing

Why choose Alfamatic hydropneumatic presses

The combination of manual lever-driven approach and the generation of pressing force through a separate, independent pressure multiplier provides MOP presses with a range of advantages:

Easy to use

The approach to the piece is achieved by simply lowering the lever, without effort. The hydraulic power is self-switching and simple for the operator.

Control of the point of contact

The operator, during the descent of the rod, can precisely control the point of contact with the piece while easily and precisely center himself on it.

Quietness

The noise of the press is limited to the development phase of the pressing stroke and respect the minimum limits established by law.

Economy

The phases of approach to the piece and return are completely manual and controlled by the operator. This results in low energy consumption.

The Advantages of Manual Operation

The combination of approaching the piece with a manual lever and the pressing force generated by a separate and independent pressure multiplier, gives the MOP presses a series of advantages:

-

Ease of use

The approach to the piece to be pressed is achieved by simply lowering the lever, without effort. The hydraulic power is automatically switched and effortless for the operator. -

CONTACT POINT CONTROL

The operator, during the descent of the rod, can precisely control the point of contact with the piece and center himself on it with ease and precision. -

Silence

The noise of the press is limited to the development phase of the pressing stroke and falls within the low limits established by law. -

Economy

The phases of approach to the piece and return are completely manual and controlled by the operator. This translates into limited energy consumption.

The Structures

The manual presses are available in three structure configurations:

Structure with Increased Light

Configuration suitable for machining pieces of greater height

Structure with Increased Light and Reach

Configuration suitable for machining tall pieces and with a bulky base

Main Features

Main Features

Main Features

Engages left hand when operating the lever. Available with push or touch actuation.

The operating and adjustment parameters of the machine are available on the front panel:

Mold support plate in steel Fe 430 B UNI 7070 with ground surface. Equipped with T-slots for fixing the mold.

The shoulder is provided with holes that allow the head unit to be lowered, reducing the working width (for sizes 07, 15 and 30 with total stroke 60 mm).

Low bending C-frame structure in Fe 430 B UNI 7070 steel with monolithic structure.

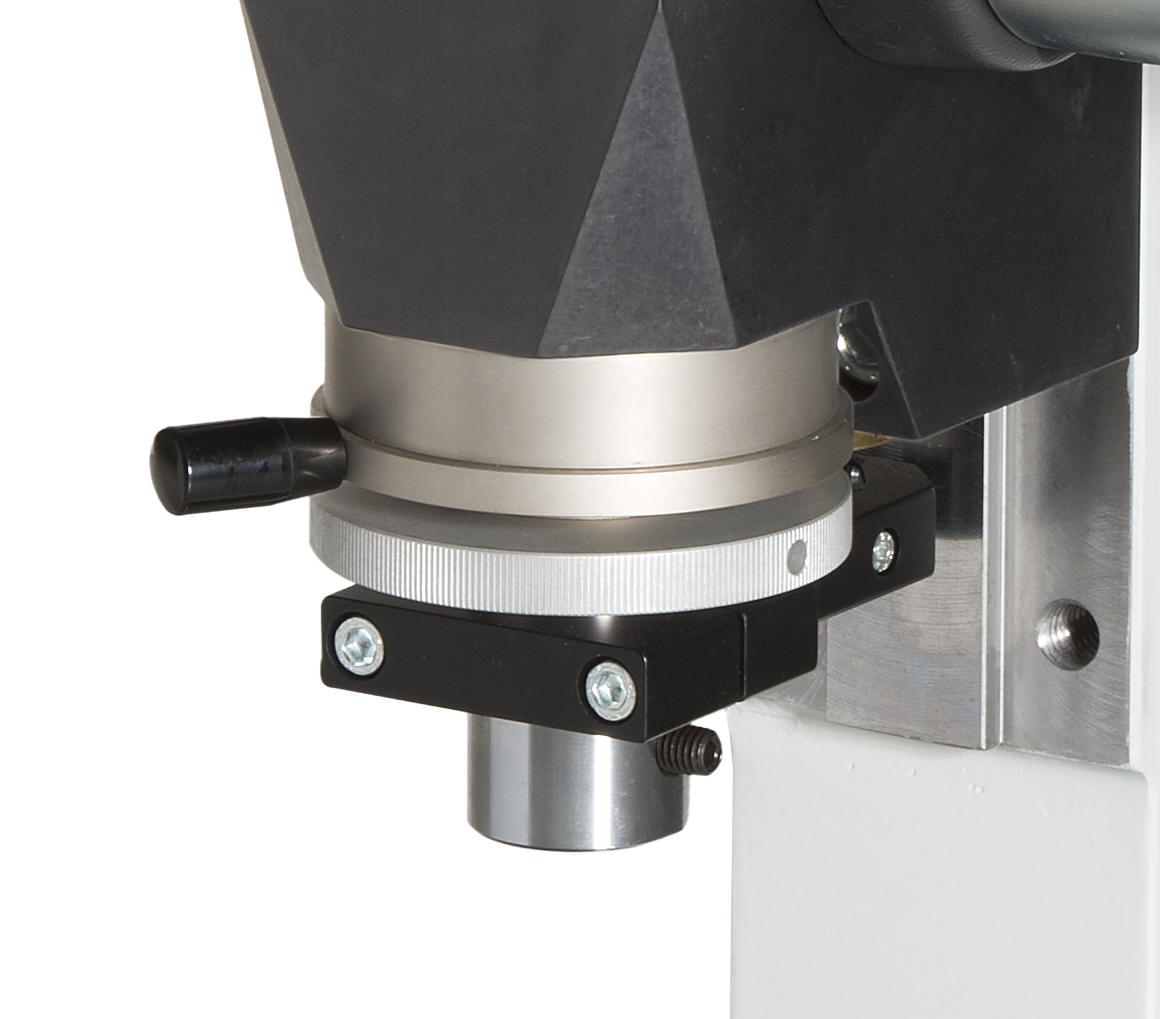

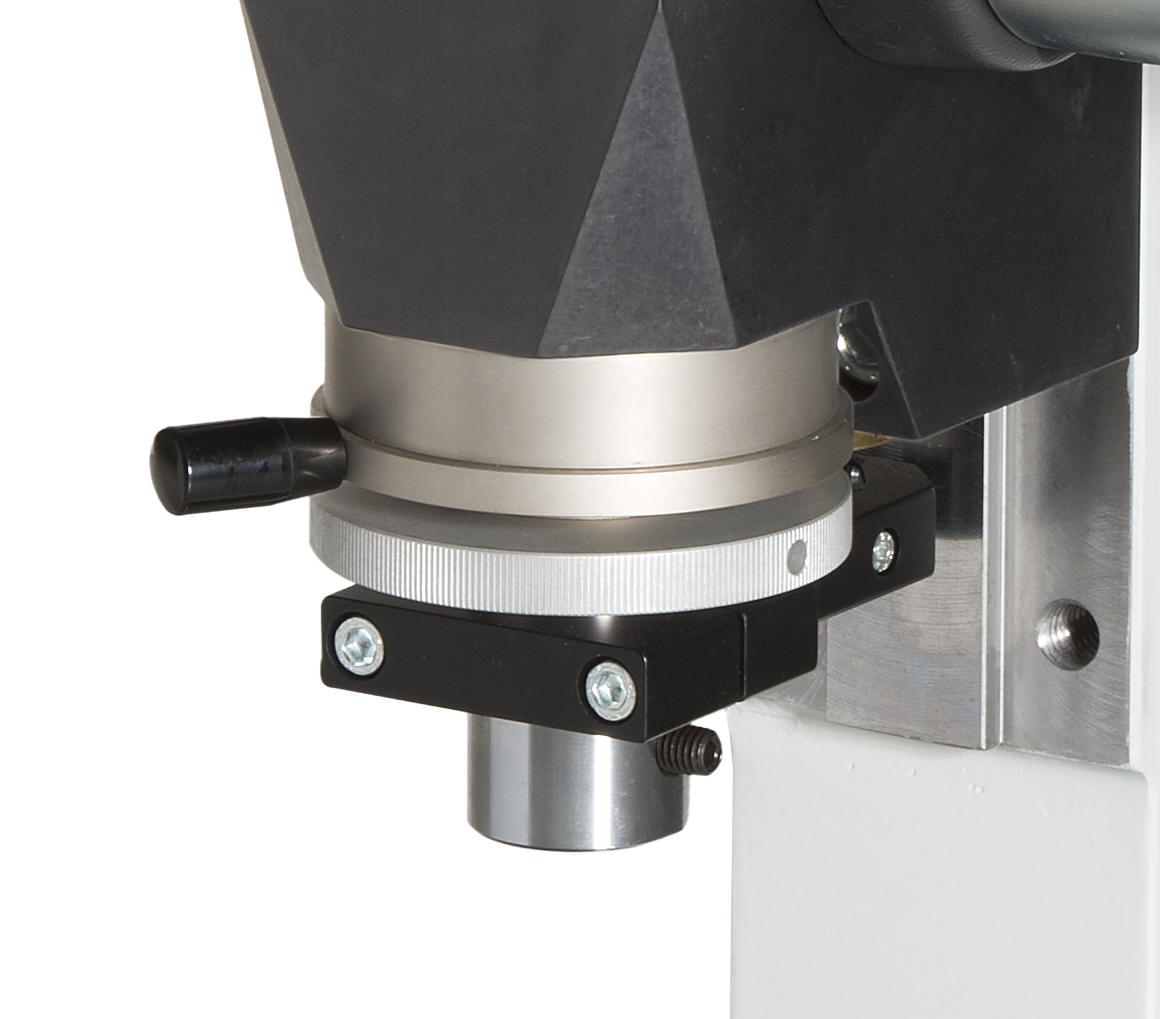

The bracket, in addition to the anti-rotation function of the press rod, allows to limit the return stroke of the rod (TDC).

It can be positioned in 4 points over 180 ° for greater working comfort. To change the position of the lever, unscrew and screw it back in the desired position.

For viewing and, if necessary, topping up the level of the hydraulic fluid.

Accessories and Options

End Stroke Mechanical Regulation

Device for micrometric adjustment of the final stroke of the rod (BDC).

Touch Button

Comfort version hand-guard side button, touch-sensitive.

Single Power Unit

With manual or motor driven operation.

Special Work Heights on Request

Special heights of work available on request.

Force monitoring pressure switch

Allows pre-setting the pressure/force at which the press halts the pressing stroke.

The Controls

The presses can be equipped with electronic systems that monitor the characteristics of each machining cycle, piece by piece.

These systems rely on pressure/force sensors and press rod position feedback—depending on the specific model. By comparing the measured values with predefined parameters, they can accurately determine whether each part meets the required quality standards.

Different configurations are available, depending on the desired level of precision:

Press-Right

- a load cell, for force measurement

- a linear encoder, for position measurement

For the interface with the user, a 7,5″ display with 640 × 480 resolution in color, full touch, is available for easy use.

Check Point

Functions:

- Displays the expressed and peak force

- Stops the unit when the set force value is reached

Range and Technical Specifications

| MOP 07 | MOP 15 | MOP 30 | MOP 50 | MOP 80 | |

|---|---|---|---|---|---|

| Power Stroke Force (kN) | 07 | 15 | 30 | 50 | 80 |

| Return stroke force (kg) | 1,4 | 1,8 | 2,2 | 2,4 | |

| Max. tool weight (kg) | 0,8 | 1,3 | 1,8 | ||

| Max. tool weight (press with load cell) (kg) | 0,4 | 0,5 | 1 | ||

| Power supply | filtered air max. 6 bar | ||||

| Total stroke (mm) | 60 / 100 | ||||

| Press handle rotation | 176° | ||||

| Power stroke (mm) | 20 (tot 60) / 25 (tot 100) | ||||

| Mechanical adjustment of bottom dead center (mm) | 10 | ||||

| Power stroke speed at 6 bar (mm/s) | 90 | 65 | 40 | 30 | |

| Consumption at 6 bar per mm of power stroke (Nl) | 0,164 | 0,349 | 0,636 | 1,098 | 1,888 |

Download

Press MOP ita-eng catalog

26/02/2024

M-OP press manual - eng

26/02/2024

Manual M-OP presses - fra

26/02/2024

MOP press manual - esp

26/02/2024

Catálogo prensa MOP_esp

23/09/2025

Catalogue Presse MOP_FRA

23/09/2025

M-OP press manual - ita

21/10/2025