ELECTRIC PRESSES

Accuracy, speed, strength and long life are the most important features of the system

Accuracy, speed, strength and long life are the most important features of the system

Electric presses offer high thrust force and precise and instantaneous processing control.

They are the ideal solution in the most varied industrial processes such as:

Bending

Bending

Drawing

Drawing

Keying

Keying

Assembly

Assembly

Clinching

Clinching

Trimming

Trimming

Chamfering

Chamfering

Marking

Marking

Straightening

Straightening

Riveting

Riveting

Pressing

Pressing

Cutting

Cutting

Compressing

Compressing

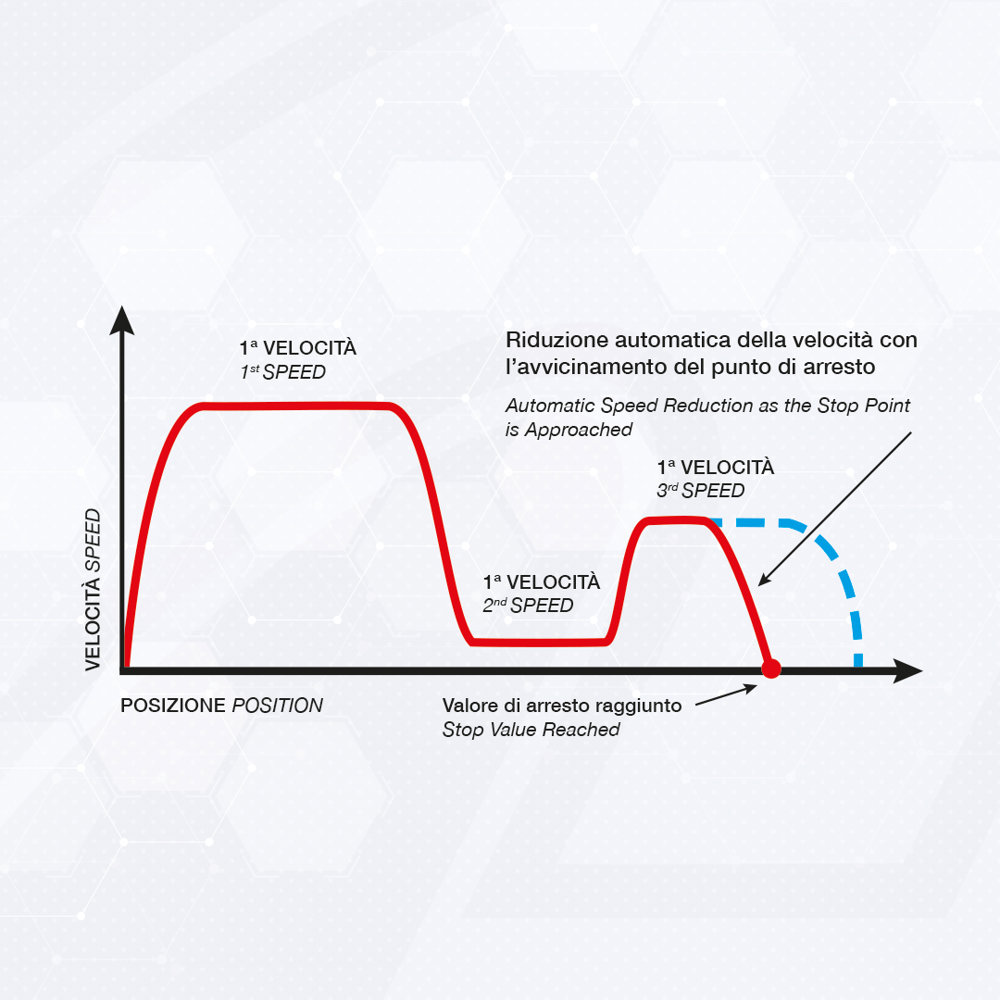

Constantly controlled movements in acceleration, speed, position. The active position control allows great precision on the stopping point, which can be improved using an external micrometric position transducer. Learn more

The possibility of reducing the working stroke guarantees a low cycle time.

Possibility of programming very complex work cycles. All the working parameters are memorized and independent of the operator's skill.

The planetary roller screw and the best mechanical and electronic choices guarantee exceptional durability, even in severe working conditions.

It does not require pneumatic and / or hydraulic power supply.

Energy consumption only in the processing phase. Reduced maintenance costs.

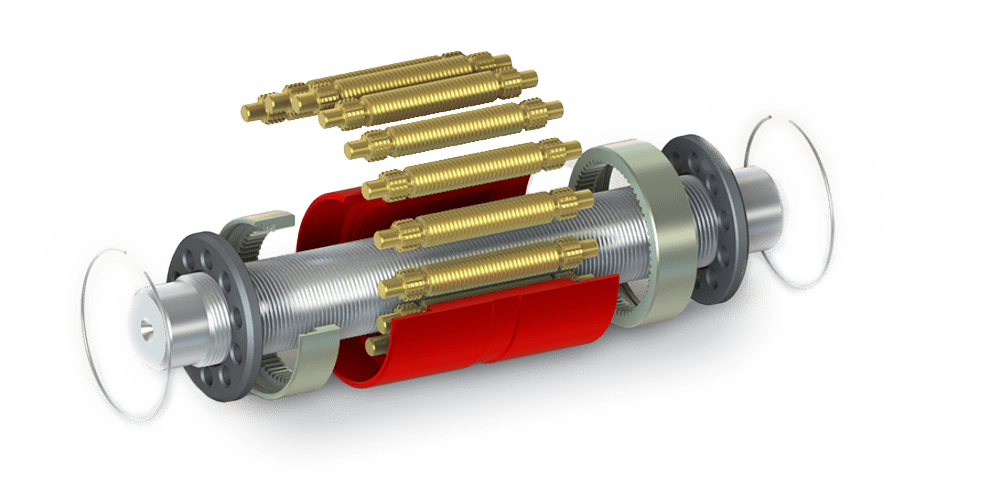

The electric cylinder in these presses, in its four versions, is the heart of the system: it can produce a force ranging from 0.05 kN and up to 300 kN, with a technology that allows great resistance to wear, high silence and low consumption.

The maximum force and speed of the cylinder depend on the different gear ratio. This determines, in some cases, the possibility of modifying the characteristics of the press at a later time to increase or decrease its strength.

Based on planetary roller technology (the best in the state of the art), the cylinder allows you to perform the heaviest machining operations with centesimal precision.

It is the tool that supervises the functioning of the press and that allows the quality control on 100% of the production.

It is interfaced with a resolver type position transducer and a strain gauge force transducer (ideal for pressing operations).

It continuously detects the position / force curve and verifies that it is contained within a continuous control band, suitably positioned.

The instrument manages the movement of the motor directly, with a precise control of the force and position values.

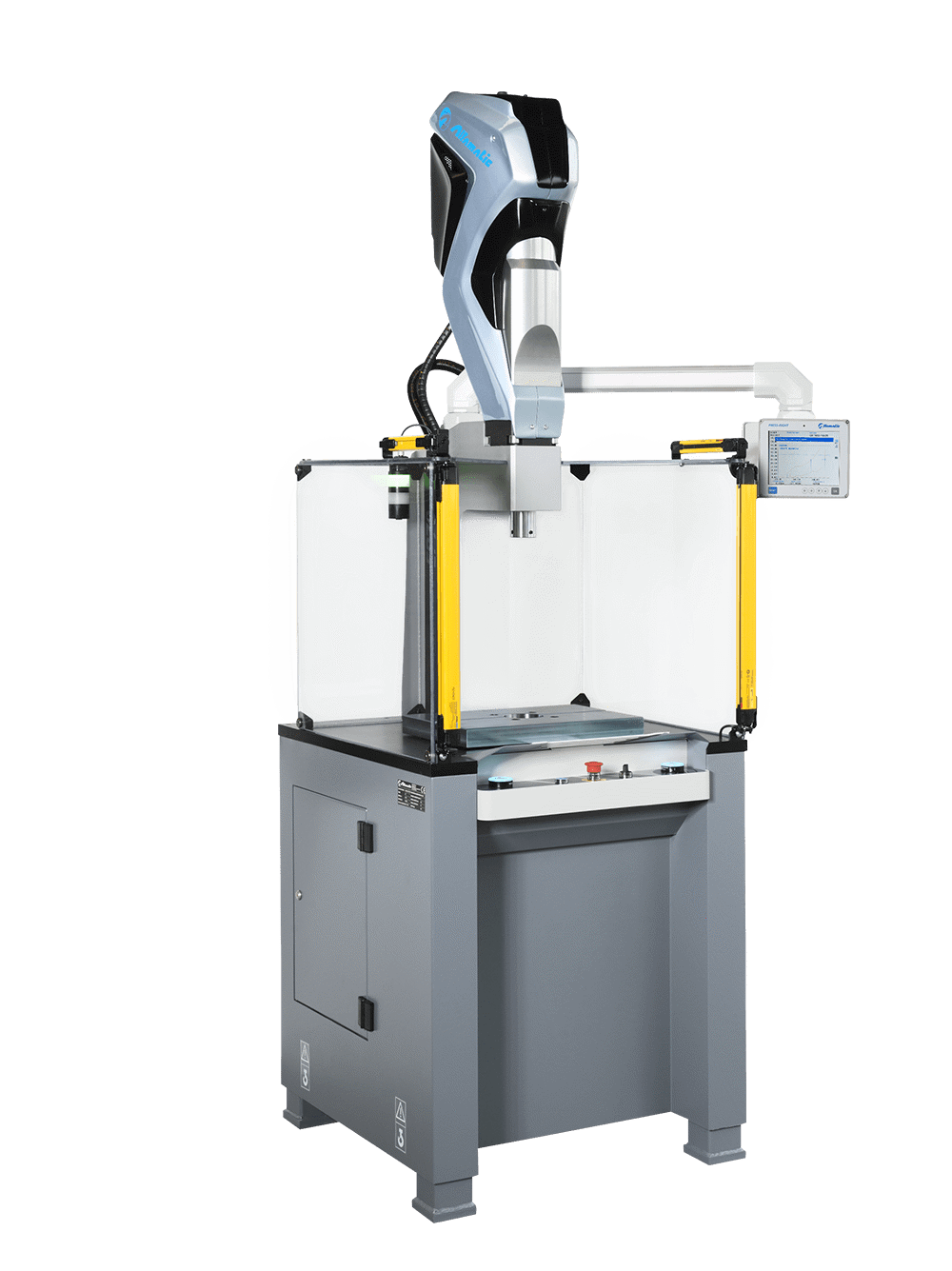

The electric presses are available in 3 different configurations:

Monolithic C-shaped structure with low bending.

It is the most suitable structure when space is needed in a transversal sense.

In steel Fe 430 B UNI 7070.

The surfaces are protected by high resistance multilayer paint.

Available with thrust forces up to 100 kN.

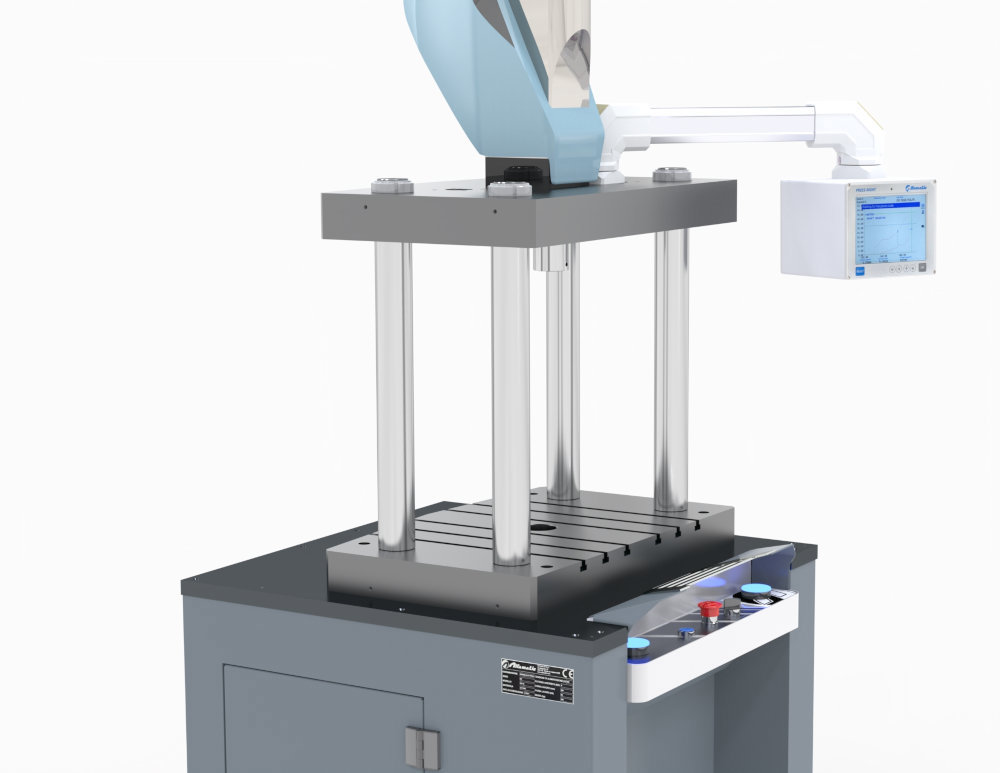

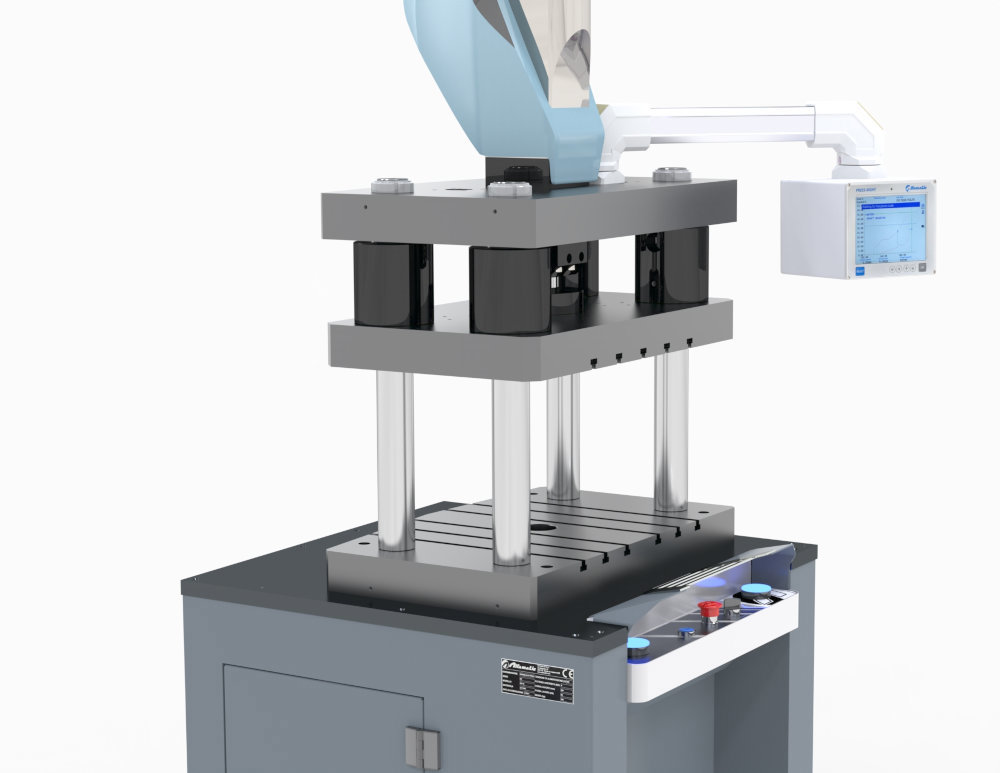

Low flex 4 column structure.

Steel structure Fe 430 B UNI 7070.

Upper and lower plates protected by burnishing treatment.

Thick chromed columns.

Low-flex 4-post structure and guided movable intermediate plate.

Steel structure Fe 430 B UNI 7070.

Upper, lower and intermediate plates protected by burnishing treatment.

Thick chromed columns.

Intermediate plate equipped with pneumatically operated fall arrest device.

Available with thrust forces up to 300 kN.

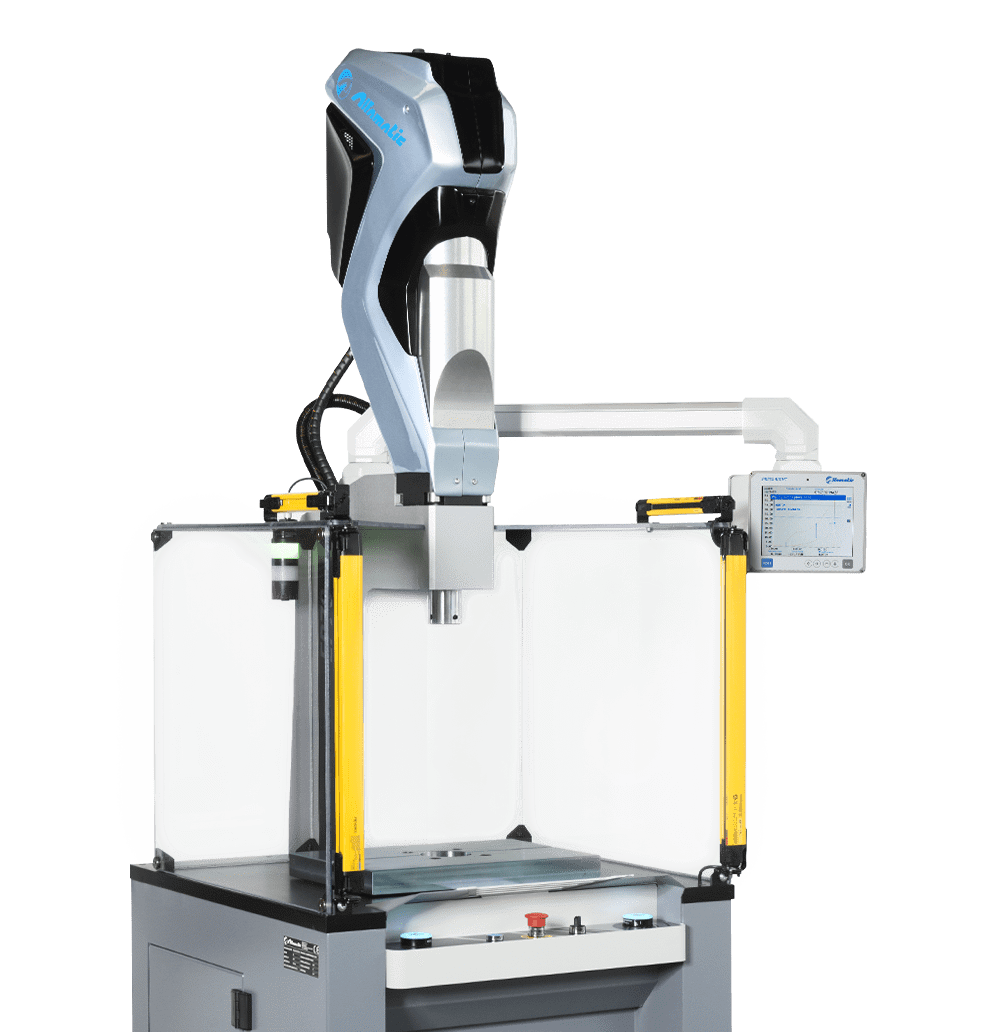

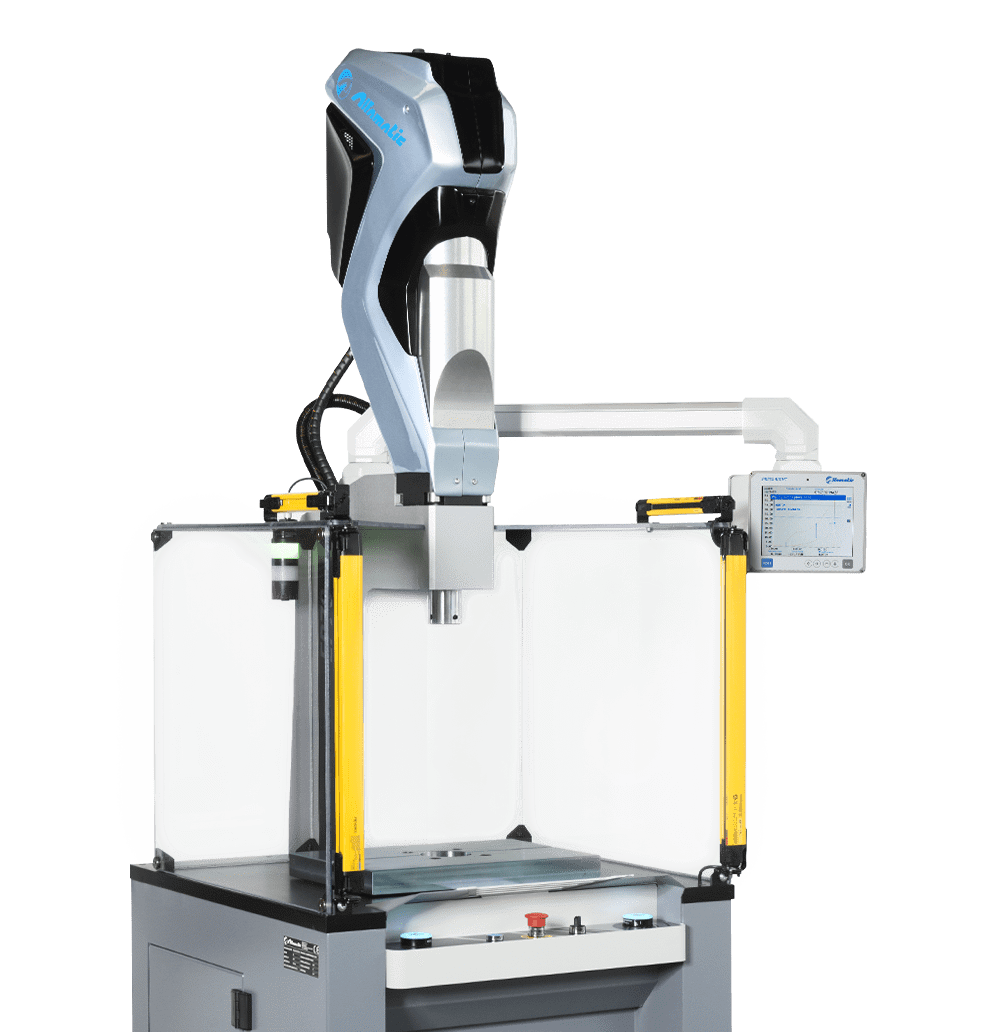

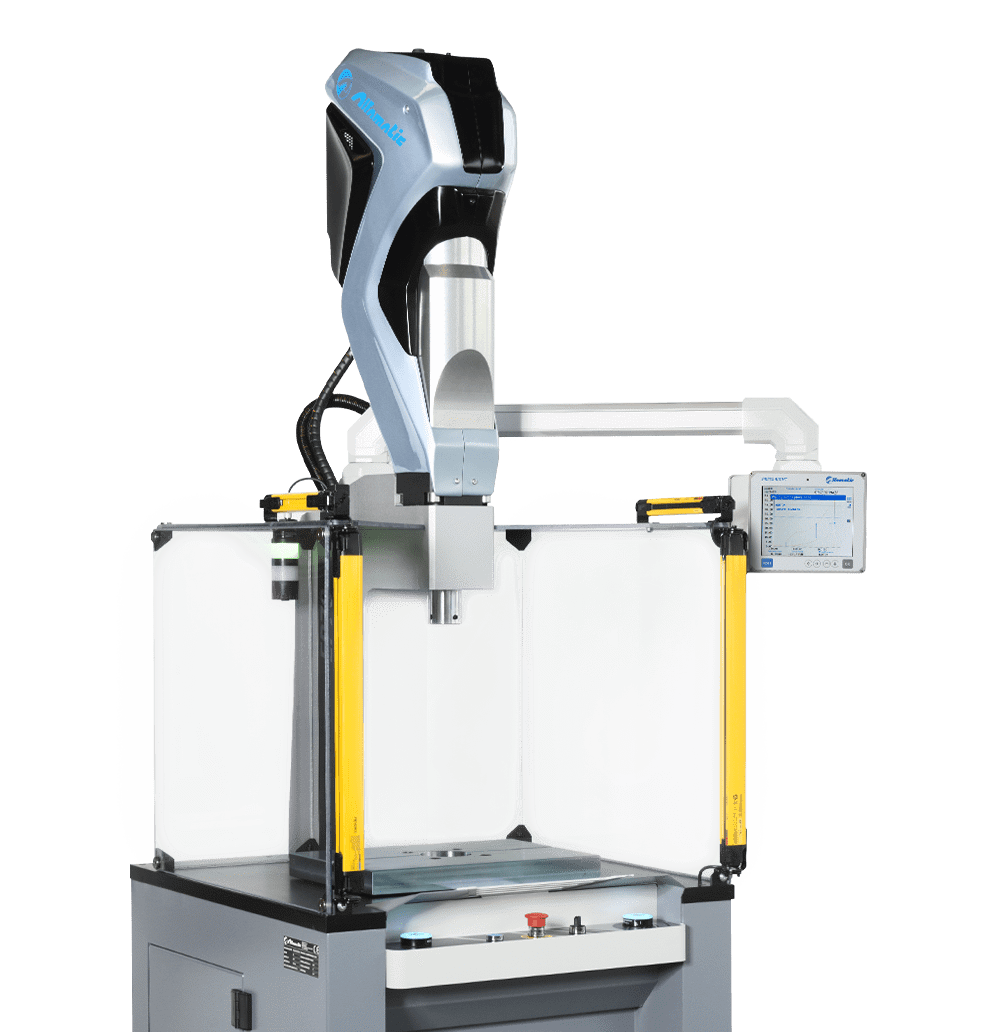

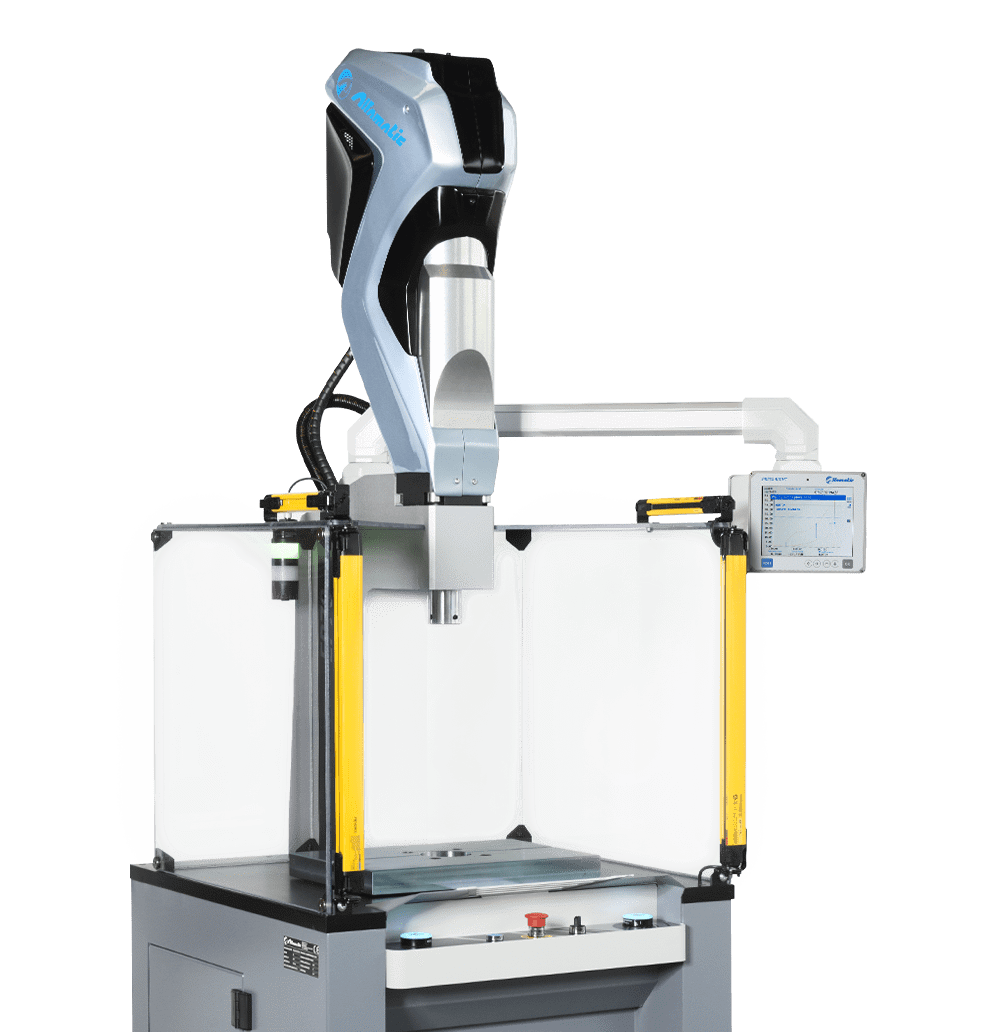

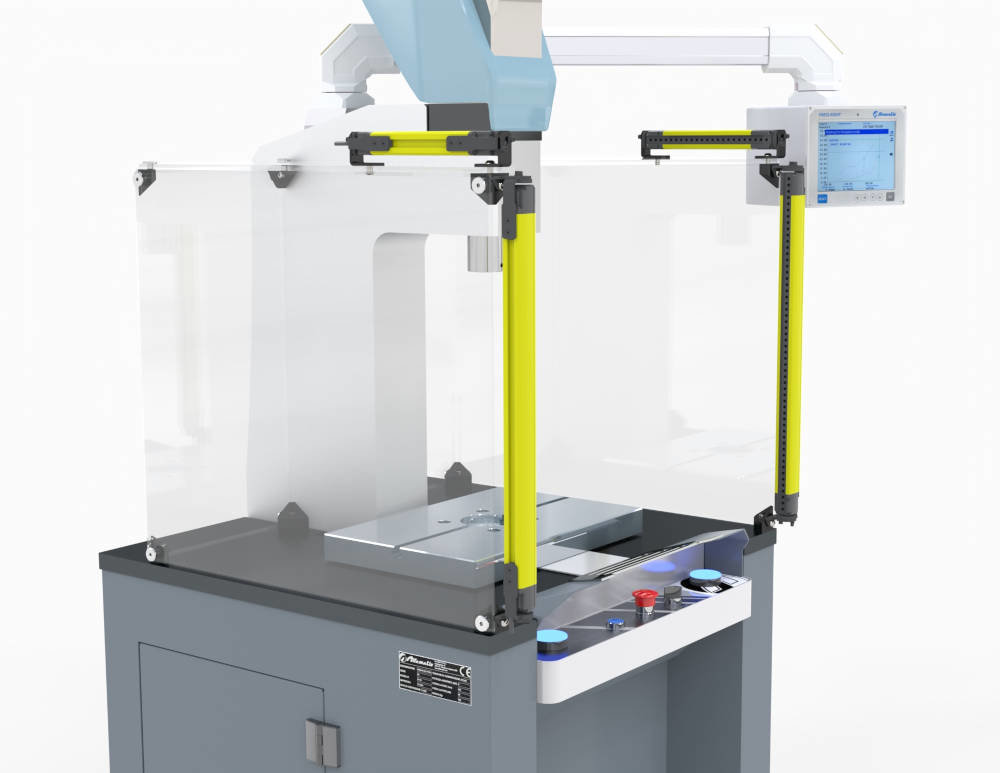

Alfamatic electric presses comply with the current strict CE safety regulations.

They are equipped with intangible light curtains and Lexan® perimeter protections.

A further pair of photoelectric barriers, positioned on the upper part of the work area, free from both visual obstacles and accessibility to the piece.

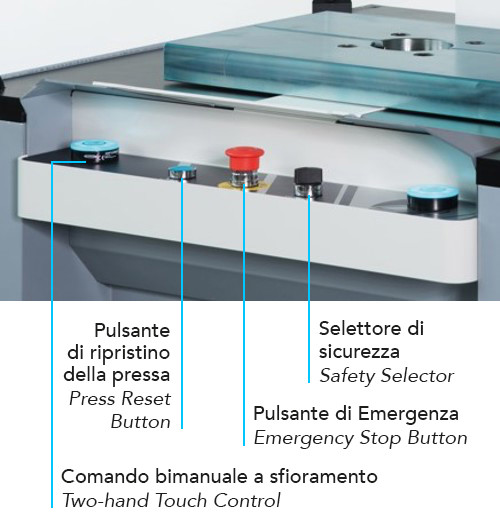

The press is activated by pressing the two-hand control.

Once the cycle has started, the operator can release the buttons and the press will continue autonomously until the pre-established parameters for the execution of the piece are reached.

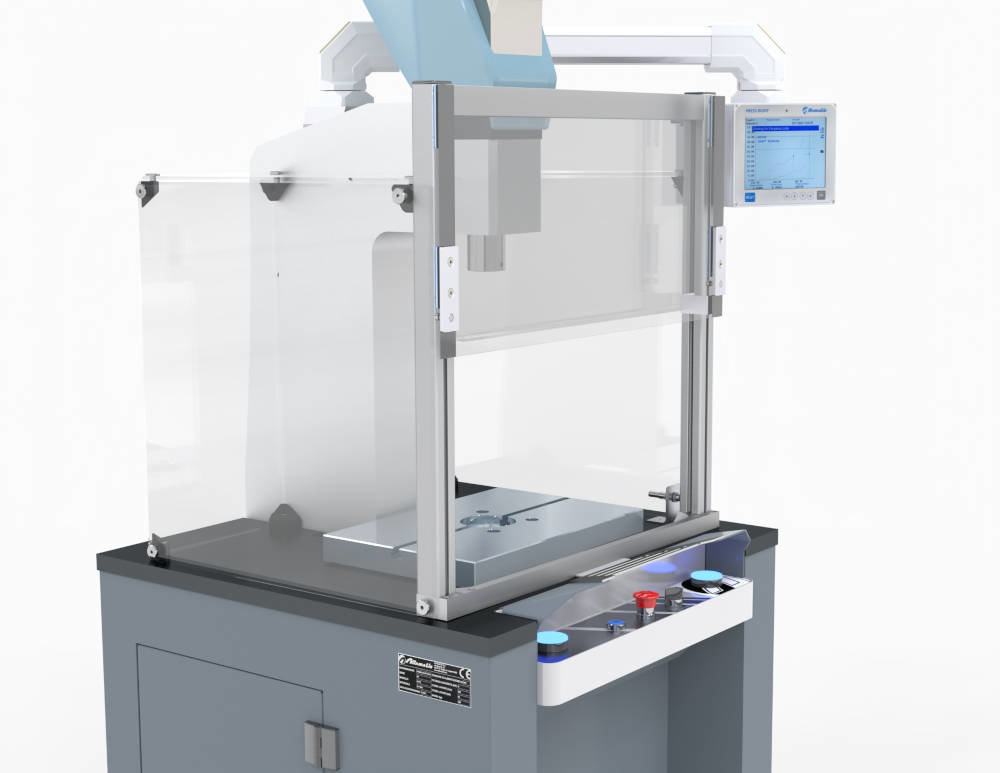

Alfamatic electric presses comply with the current strict CE safety regulations.

The CA version is equipped with a pneumatically operated mobile front gate and Lexan® perimeter guards.

This type of protection is particularly suitable if the operation to be performed presents the possibility of projection of the piece during the pressing phase.

The press is activated by pressing the two-hand control.

Once the cycle has started, the operator can release the buttons and the press will continue autonomously until the pre-established parameters for the execution of the piece are reached.

Available with thrust force from 1 to 300kN. Depending on the size, equipped with roller or recirculating ball screw. Models 1-2-5 are equipped with an external load cell, placed on the end of the rod.

• C-framed, monolithic, in steel Fe 430 B UNI 7070.

• With 4 columns with upper and lower plates in Fe 430 B UNI 7070 steel and supporting columns in chromed C45 steel.

In steel Fe 430 B UNI 7070 with ground surface. Equipped with T-slots for fixing the mold.

To operate the press and control the operating parameters. It is equipped with touch buttons for maximum ease of use:

With perimeter protections in Lexan® and front part with free access, protected by immaterial barriers (photo-electric; in compliance with current CE regulations).

Incorporated in the right side of the table, easily accessible for inspection and maintenance.

Equipped with adjustable feet (height to be determined when ordering).

The external HPT load cell allows precise measurement of low forces, further extending the versatility of Alfamatic electric cylinders.

It allows to measure, with micrometric precision, the true position of the tool with respect to a reference point on the piece, eliminating the inaccuracies due to the play and deformations of the structure.

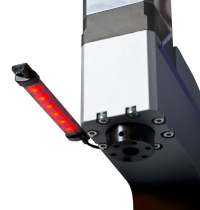

Traffic light signaling accessible work area. A luminous device signals the press at rest and the accessibility of the work area. This avoids the machine blocking caused by the accidental activation of the barriers during the movement of the rod.

For a better visibility of the work area.

Specific lubricating grease for presses with planetary roller screws.

It allows, through the greasing hole, the addition of grease inside the electric actuator nut.